Prototype to Production

From prototype to production, we deliver excellence at every stage.

Rapid Production

Fast turnaround time for production units

AI Inspection

AI based inspection to identify defects during production

Pb-Free Support

Pb-Free PCB assembly support

ESD Packaging

Packed and shipped in ESD secure covers

comprehensive assembly solutions

Explore our assembly expertise: SMT, through-hole, and turnkey solutions.

Capabilities Overview

our comprehensive capabilities and expertise at a glance.

PCB Size Limits

- Maximum Size: 510mm x 460mm

- Minimum Size (Production): 50mm x 50mm

- Minimum Size (Prototyping): Limitless

SMT Component size

- 0201 to 102mm

- Micro SMT: Micro BGA, Large BGA, CSP, Fine Pitch, QF

- Modules/SOM

order flexibility

- No MOQ

- Suitable for Prototype, High-Mix Low Volume, or High Volume

conformal coating

- Acrylic Conformal

- Coating Parylene Coating

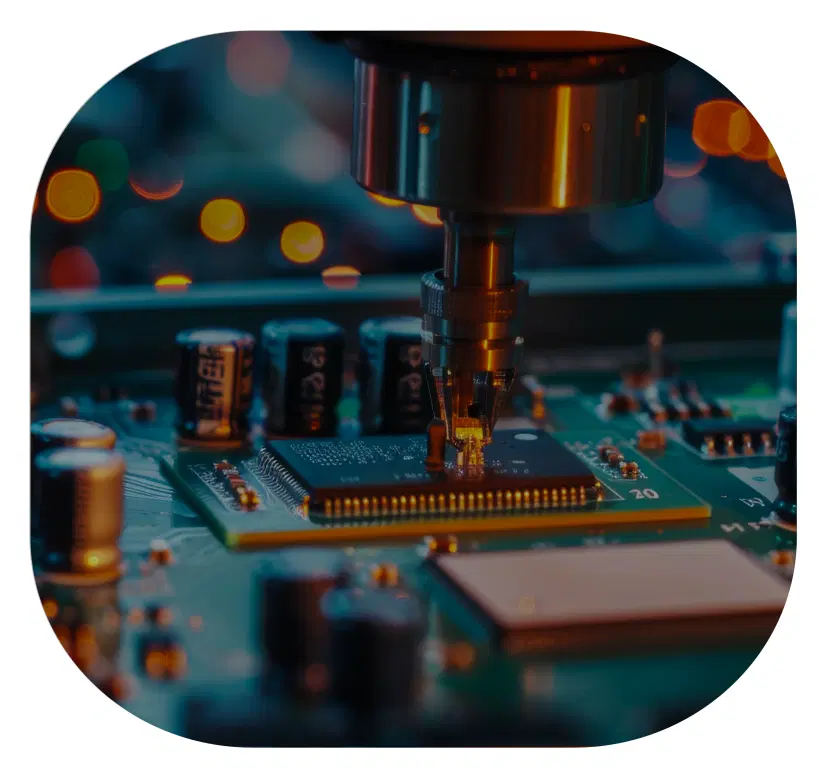

Streamline PCB Assembly

Fully Automated SMT line and Wave Soldering for Through hole component assembly.

We specialize in Printed Circuit Board Assembly (PCBA) services in India, shipping globally, with expertise in complex PCB design and assembly. Our state-of-the-art facility features advanced pick and place machines, for handling surface mount components, and wave soldering for through-hole components. Additionally, we offer X-ray inspection for BGA components, ensuring precision and quality. Our online order system provides real-time cost estimates, streamlining the process for your PCBA needs.

8 Zone Reflow Oven

BGA Support with X-Ray Inspection

Turn-Key Support

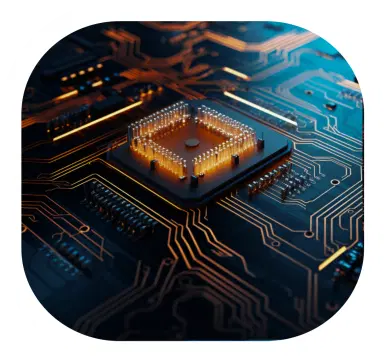

PCB Assembly

Assemble with precision, deliver with confidence. Our PCB assembly services offer tailored solutions for seamless integration.

Assembly Types

Surface mount and through hole assembly on one or both sides of the PCB.

Assembly Quality

Fully automated state-of-the-art assembly line for unparalleled quality, reliable and timely delivery.

Stencil Options

Support for both frameless and framed stainless steel metal stencils for solder paste application. Framed stencils mandatory for certain components.

Lead Options

Both leaded and lead-free (RoHS) assembly options available.

Minimum Board Size

50mm x 100mm for machine assembly, smaller boards need to be panelized.

Component Support

Components in Reel, Cut-tapes, and Tray formats supported.

Circuit Board Shape

Non-rectangular boards must be panelized with side rails (5mm) on the longer edge for machine assembly.

Functional Testing

After the assembly of printed circuit boards, we conduct functional testing, including short/open checks, power-up tests, and basic voltage tests at designated points. For batch sizes of 50 or more, we recommend defining a customized test procedure to ensure comprehensive testing of the printed circuit boards assembly. Additionally, if your board features a microcontroller, we support device firmware upgrades and test firmware using standard Jigs, guaranteeing the optimal functionality of your printed circuit boards.

begin with

BOM upload

Jumpstart your PCB assembly process by uploading your Bill of Materials (BOM) to receive instant automated quotes based on your gerber and BOM combination.